Methodology

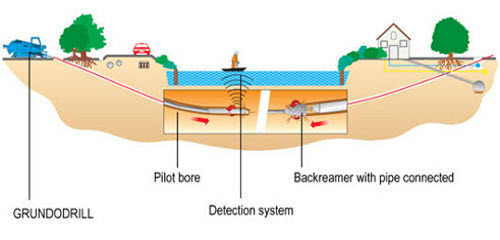

HORIZONTAL DIRECTIONAL DRILLING METHOD

The HDD method contains impact support and is called the Grundodrill Technique. It enables Trench less Installation Up to 500 m length. The Spectrum of Application includes all Pipe Construction Measures within the bounds of gas, district heating and Drinking Water Supply, the installation of Pressure lines for sewers as well as cable protection pipe for Telephone or television Cables. The HDD Method is Extremely Protective towards the environment and causes no ecological damage at all. The HDD method is advantageous because surfaces worth conserving are neither broken up nor damaged, restoration and Repair are not required, witch leads to high economical advantages. There are several reasons for the application of the directional technique in central town areas, The mainly concern the construction costs, construction periods, permission Procedures, soil displacement surface restoration and the traffic, compared to open Trenching methods. the normal course taken by the drilling operation Includes planning , preliminary survey ,selecting the drilling units and drilling tools, pilot bore and detection, back reaming or upsizing bore and pulling in the pipe. To overcome mechanical soil resistance high thrust and tension forces are required. The application of bentonite might relive the pilot bore and the pipe traction and provide the ability to steer in difficult soil qualities.

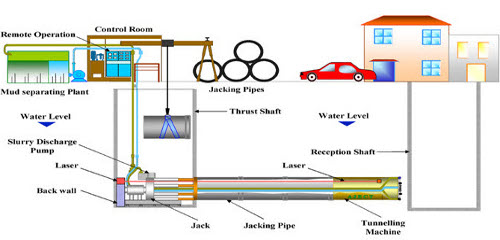

MICROTUNNELING METHOD

Micro tunneling is a process that uses a remotely controlled, Micro tunnel boring machine (MTBM) Combined with the pipe jacking technique to directly install product pipelines underground in a single pass, this process avoids the need to have long stretches of open trench for pipe line laying, which causes extreme Disruption to the community. Typical Microtunnel equipment spread consists of an MTBM matched to the expected Sub surface conditions and the pipe diameter to be installed, hydraulic jacking system to pipe jacking the pipeline.

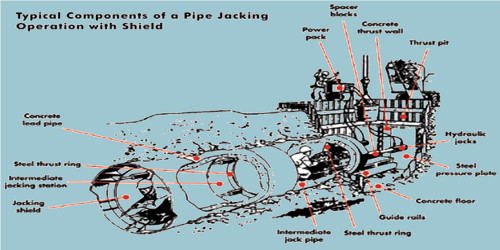

PIPE JACKING TECHNIQUE

Pipe jacking generally referred to in the smaller diameters as micro tunneling is a technique for installing under ground pipe lines, Ducts and culverts, powerful hydraulic jacks are used to push specially designed pipe through the ground behind a shield and at the time. Excavation taken place within the shield, the method provides a fixable Structural watertight finished pipe line, as the tunnel is excavated pipe in the range of 150mm to 3000mm can be installed. To install a pipeline thrust and reception pits are constructed usually at manhole positions, the diminutions and construction of a thrust pit may vary according to the specific Requirement, A thrust wall is constructed to provide a Reaction against the jack, High pressure jacks provide the substantial force require for jacking concert pipes.

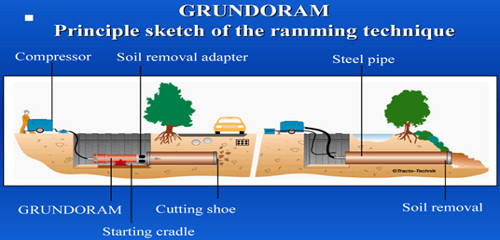

RAMMING METHOD

Dynamic Ramming Method used unsteered Ramming with Pipe Propulsion along with the use of Pneumatic Pipe Ramming Machine. With these, Open Steel Pipes Can be laid beneath Railway Tracks, Highways, and Rivers, either as Protection or Product Pipes, with Diameters up to 2000m from Lengths of up to 80m in the Soil with out using Pressing abutments. The Ram is driven by Compressed air and has cotter Segments to establish a Connections between the Machine and pipe. Advantages of the method include Surfaces worth conserving are not broken, Restoration is not required, low social cost, acknowledged Procedure, short set-up times, short Pipe laying times, no Pressing abutment, No conveyor Spiral, No Flooding when working on River crossings, No elaborate Pits, simple operation Technique and adaptation to all Pipe diameters with a Special Ram cone.

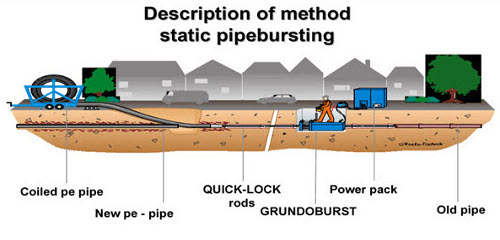

DYNAMIC PIPE BURSTING

In the Method of dynamic Pipe Bursting, the Bursting Machine is pulled by a winch through the old Pipe Meant to be renewed. During this Procedure, the old Pipe is destroyed by Dynamic Impact energy and the fractured Particles are pushed into the Surrounding soil, while the new line, in the same width or one size larger, is pulled in at the same time. The old pipe line is actually cut open by the roller blade immediately Followed by the expansion head, Advantage of this method include Path of the old pipe can be used , bursts grey cast iron, asbestos-cement, stoneware, concrete and Plastic, Pipe bursting can also cut ductile grey cast iron and steel new pipe with new longevity improvement of the hydraulic capacity, because the new pipe with to be installed is 1 or 2 sizes larger, no reduction of the cross section, applicable for all types of damage, good bedding conditions, Short equipping time and simple operation technique, high capacity of up to 150 m.

DIRECT-BURIED CABLE (DBC)

Direct buried cable is a kind of communications or transmissions cable which is especially designed to be buried under the ground without any kind of extra covering pipe to protect it, by using joint cutter machine, for 10mm X 150mm deep Groove cutting in surfaces made of concrete or asphalts. Advantage of this method most cable of this kind is bundled fiber-optic in Nature. Direct-buried is cheaper and easier to lay than other kinds of cable that require Protection from the earth. However, DBC is also easily cut during digging or excavations. As a result most direct-buried cable is found on side roads and protected by GI-Flat, Foam, Rubber and sealant chemical.